© 2025 The authors. This article is published by IIETA and is licensed under the CC BY 4.0 license (http://creativecommons.org/licenses/by/4.0/).

OPEN ACCESS

Sewer trench backfilled with natural reactive clays can cause devastating deformations due to reactive clay being susceptible to swelling and shrinkage upon changes in moisture content. Therefore, this research studies the influence of recycling waste materials in enhancement the geotechnical properties of backfilling materials. Crushed glass was utilized as waste material and blended with reactive clay at different proportions being 0%, 20%, 30%, 40%, 50%, 60%, 70%, 80% and 100%. Experimental tests were carried out to explore the optimum glass content by investigating the physical and mechanical properties of clay-glass mixtures, which included swelling, shrinking and strength characteristics. The findings presented that increasing glass proportion raised maximum dry density and reduced optimum moisture content. Swelling, shrinkage and strength tests showed that no significant improvement beyond 40% glass content, which was recommended as the optimum glass content. The outcome of this study enhances understanding of clay behavior with recycled glass, promoting sustainable construction.

crushed glass, reactive clay, shrink-swell cycle, waste materials

Reactive clayey soils have been considered to be one of the more intricate soils that cause extensive damage to civil engineering structures worldwide. Reactive soil is characterized by its high plasticity and typically contains montmorillonite and other active clay minerals. This type of soil presents a common problem, raising concerns among researchers regarding the design, protection, and maintenance of structural systems. Reactive soils are prevalent in arid/semi-arid regions, where even moderate expansiveness can lead to significant structural damage [1, 2]. Similarly, in humid environments, high plasticity index reactive soils have a risk to structures. Various factors influence the behavior of reactive soil, with moisture availability and the quantity and type of clay-size particles being among the most significant. Changes in water content cause volume fluctuations, resulting in either swelling or shrinkage, hence the term “swell/shrink soils” [3]. Although chemical alterations can induce expansion, reactive soils predominantly comprise clay minerals prone to swelling and shrinkage. Greater clay content in the soil increases the potential of swelling, as clay attracts water. Conversely, as the soil loses moisture, it shrinks. Research suggests that safe expansion percentages for most reactive clays typically equal or fall below 10% [4]. Therefore, it has become significant to take into account the issue of reactive soils in pavement design and construction.

To mitigate this problem, different strategies have been developed, involving both chemical and mechanical stabilization approaches. Lime and cement are two most commonly used additives for chemical stabilization of expansive soils [5]. However, there are several disadvantages associated with chemical approach, involving two harmful chemical reactions: carbonation and reaction with sulfate salts present in the soil. These processes can result in soil damage, expansion, and deterioration, often resulting in strength loss [6]. Additionally, chemical stabilization is known to have adverse environmental effects, particularly the release of CO2 during the production of stabilizers like cement [7]. Despite these drawbacks, chemical additives remain extensively utilized in diverse geotechnical engineering applications, including enhancing subgrades, lining channels, constructing earth dams, and building embankments. This persistent use is due to their advantages, including reliability, availability, and proven effectiveness, which are perceived to outweigh their disadvantages [8]. The mechanical stabilization involves compaction [9], pre-wetting [10], drying-wetting cycles [11, 12], reinforcement [13], reactive layer replacement with an inert material [14], barrier systems to rule moisture flow into reactive soil [15] and solid waste [16, 17].

Waste material refers to any substance produced from industrial processes that lacks enduring utility [18]. The growing of waste materials amounts and insufficiency of landfill regions highlight the requirement of looking for inventive ways to recycle waste materials. Recycling waste materials can reduce the virgin materials request and consequently lead to a more sustainable environment [19, 20].

The performance of various kinds of waste materials has been studied in soil stabilization. Reactive soils have been stabilized using industrial wastes such as Fly ash, Rubber, aluminium residue, recycled asphalt and slag with/without a binder such as lime, cement, bitumen and calcium chloride [13, 21-29]. All these studies have confirmed the applicability of using waste materials in enhancing reactive soil properties.

Glass waste has been deemed at the top of the challenging waste materials list. More than 130 million tons of glass were produced worldwide in 2018, about 20% was only recycled [30]. Usually, glass spends more than 400 years to biodegradation, therefore, it has been significant to repurpose it across different uses. The physical properties of crushed glass, such as its increased permeability and strong resistance to crushing could develop its usage in civil engineering applications and constructions [31].

Many studies have explored the viability of incorporating recycled glass into road construction. Arulrajah et al. [32] and Disfani et al. [33] investigated the use of glass blends as unbound aggregates for pavement system. They found that combinations of recycled glass, recycled concrete, and waste excavation rock meet the requirements for subbase applications but may not be entirely suitable for base applications. Mohajerani et al. [34] provided an outline of research conducted on repurposing crushed glass as an aggregate in pavement structure, revealing the promise of utilizing crushed glass in pavement applications. Mohsenian Hadad Amlashi et al. [35] explored the viability of incorporating recycled glass as a material in base and subbase applications. The findings indicated that recycled glass had a higher drainage potential than limestone aggregates. Drainage characteristics are significant for the effectiveness of unbound base and subbase layers, especially when considering the interaction between water and the structure of the pavement. Yaghoubi et al. [20] and Teodosio et al. [36] suggested the use of recycled glass for filling deep sewer trenches situated in non-traffic areas.

In recent years, numerous research works have explored the applicability of utilizing recycled glass in enhancing the reactive soils geotechnical characteristics [37-42]. These investigations conducted experimental analyses on recycled glass particles smaller than 0.075 mm, disregarding gradations larger than 0.075 mm. Including large particles may increase the soil's properties. The recycled glass powder particles demonstrate pozzolanic traits, as observed by Kalakada et al. [43]. As the particle size decreases, the potential of a pozzolanic reaction increases. In contrast to the sand-sized recycled glass (RG) utilized in this research, glass powder contributes through the chemical stabilization of soils rather than relying solely on mechanical stabilization. Sand-sized RG was chosen for this study due to the limited research available on non-powder RG. In Iraq, there is sufficient availability of sand-sized recycled glass (RG), which is priced 25–50% lower than native sand. While, the extra processing needed to create glass powder leads to increased recycling costs and energy consumption when compared to producing glass in sand-sized particles [44].

An unexplored area concerns the long-term swelling potential influenced by 'cyclic swell-shrink', a method for studying climatic-induced swell-shrink [2, 45]. Researchers applied one-dimensional consolidation theory to model climatic effects on expansive soils' volumetric behavior, requiring controlled suction to measure swelling and shrinkage potential. While suction induces hydraulic hysteresis in void ratio throughout wetting and drying alternations [46], moisture content correlates linearly with void ratio during cyclic wetting and drying [47], validated by Tripathy et al. [45]. This behavior, attributed to void ratio and moisture ratio showing hysteresis with suction, led several researchers to adopt the cyclic wetting and drying process to investigate the climatic impacts on volumetric behavior and structural design [2, 12, 48, 49]. For compacted clays, the second cycle of swell-shrink may exhibit significantly higher swelling values, often exceeding those of the first cycle by more than double [45]. Hence, it is essential to incorporate at least one method for assessing climate effects in research aimed at replicating real-world conditions for long-term use.

While numerous studies have investigated using glass for clay stabilization, they predominantly focused on powdered or fine glass and cement glass powder in small amounts. There's a significant gap in research regarding stabilizing expansive clay with coarse crushed glass, despite its widespread availability in places. Additionally, the authors note a lack of investigation into the climatic impact on the volumetric behavior of RG-stabilized clay. Although both chemical and mechanical stabilization methods enhance reactive soil characteristics, factors such as particle size and content influence the efficacy of mechanical stabilization using recycled glass. However, there is currently no extensive study investigating the combined influence of recycled glass size and content on the volume and strength attributes of expansive clay subgrades treated with recycled glass.

Therefore, this research conducted a thorough testing of how the mechanical characteristics of clay soil change when mixed with glass particles of varying sizes and proportion. Specifically, the research explored the impact of incorporating significant amounts of recycled glass, including particles up to 4.75 mm in size, on the mechanical properties of expansive clay. Additionally, the study examined the long-term performance of the treated clay by analyzing how climatic conditions affect its volume behavior over time. To achieve this aim, the flow chart shown in Figure 1 was followed. Firstly, the clay and recycled glass physical properties were obtained. Next, static testing including one-dimensional swell and UCS were conducted to explore the swelling magnitude and strength of reactive clay stabilized with recycled glass. Finally, the impact of climate on volumetric characteristics (for the long-term) was explored using the shrink-swell cycle test. This study advocates for the use of recycled materials to improve the performance of clay materials. Recycled glass can be substitutional in construction projects to traditional methods which are relatively costly and less environmentally friendly. This research conducted a thorough examination of how the mechanical characteristics of clay soil change when mixed with glass particles of varying sizes and quantities. Specifically, it explored the impact of incorporating significant amounts of recycled glass, including particles up to 4.75 mm in size, on the mechanical characteristics of clay. Additionally, the study examined the extended-term performance of the treated clay by analyzing how climatic conditions affect its volume behavior over time.

Figure 1. Flow chart for investigation the impact of adding glass on the traditional backfill soil properties

The compressive characteristics of clay-aggregate mixtures are affected by either the clay component or the aggregate component, depending on their dominance. Below a certain "transition content", the blend's mechanical response is governed by the clay, while above it, the behavior is controlled by aggregate particles. With low aggregate levels, clay governs the blend's behavior due to limited contact with aggregate particles. Increased aggregate content introduces additional voids between clay and aggregate particles, leading to greater compressibility. While, maintaining constant dry density of clay results in increased compactness as clay is compacted between aggregate particles during compaction. Trapped clay particles experience higher stresses, rendering them harder than other areas of the mixture. These hardened clay portions serve as bridges between adjacent aggregate particles, stabilizing the force chain and resulting in a less compressible blend compared to pure clay [50, 51].

3.1 Materials and suggested blends

Reactive clay and crushed glass were utilized in this research to simulate the traditional backfilling and waste material. The crushed glass consisted of different sizes, with a maximum size of 2.36 mm. Based on the ASTM-D854 procedures [52, 53], the clay specific gravities (Gs) and crushed glass (G) were 2.72 and 2.43, respectively.

Figure 2. PSD of clay, glass and suggested blends

Based on ASTM-D422 [54], The particle size distribution (PSD) curves were measured and depicted in Figure 2. This research aimed to select blends with PSD ranging between the PSD of the suggested clay and that for the glass. Thus, blends with glass content ranging from 20% to 80% were recommended and compared with the performance of the selected reactive clay (Figure 2). The specific gravities of the selected mixtures are presented in Table 1. In this study, each blend was tested multiple times until the results were within an acceptable range of difference. If the initial tests showed a difference of more than 3%, additional samples were tested until the difference was acceptable. This ensured the reliability of the average value obtained for each blend.

Table 1. The clay-crushed glass blends physical properties

|

Material |

Gs |

Cu |

Cc |

USCS |

|

100% C |

2.73 |

- |

- |

CH |

|

80%C-20G |

2.68 |

- |

- |

CH |

|

70%C-30G |

2.66 |

- |

- |

CH |

|

60%C-40G |

2.64 |

- |

- |

CH |

|

50%C-50G |

2.62 |

- |

- |

CH |

|

40%C-60G |

2.59 |

- |

- |

SC |

|

30%C-70G |

2.57 |

- |

- |

SC |

|

20%C-80%G |

2.55 |

- |

- |

SC |

|

100% G |

2.5 |

6.24 |

1.55 |

SW |

|

Cu: coefficient of uniformity, Cc: coefficient of curvature, USCS: Unified Soil Classification System, CH: clay with high plasticity |

||||

3.2 Compaction

Standard Proctor compaction tests were conducted in accordance with the study [55] procedures on the blends outlined in Table 1. The clay and recycled glass were initially dried in ovens at temperatures of 105℃ and 50℃, respectively. These blends, with proportions detailed in Table 1, were combined with varying percentages of water and then placed in sealed polythene bags for 7 days to ensure uniform water distribution throughout the specimens. Compaction was carried out in three layers, each receiving 25 blows, employing a compaction effort of 600 kN-m/m³ within a cylindrical mold measuring 101 diameters × 116 length. This process was repeated for different water contents, and the optimum moisture content (OMC) and corresponding maximum dry density (MDD) were determined.

3.3 One-dimensional swell test

To seek the influence of glass on the soil swelling after compaction, one dimensional (1-D) swell test was conducted. According to the expansivity categorization recommended by Seed et al. [56], the 1-D swell test [57] was performed on clay specimens blended with different glass proportions. Cylindrical samples, 50 mm in diameter and 20 mm in height, were prepared at the Optimum Moisture Content (OMC) and Maximum Dry Density (MDD). These samples were immersed in water and allowed to swell under a pressure of 6.7 kPa until negligible volume change was observed. This stress level was recommended for categorizing the expansiveness of both the clay and the clay-glass mixture, as per the recommendations by Seed et al. [56] proposed method. Expansivity refers to the potential volume change resulting from water adsorption by minerals in the soil. Subsequently, a series of stresses ranging from 12.5 to 1600 kPa were applied according to ASTM-D2435/D2435M [58]. Swelling was measured at the conclusion of testing.

3.4 Unconfined compressive strength

Specimens (75 mm diameter $\times$ 150 mm height) prepared at different glass contents (0%, 20%, 30%, 40%, 50%, and 60%) were compacted at OMC and MDD. Next, Specimens were subjected to loads at a displacement rate of 1 mm/min to make sure that the experimental testing would end during 10-15 minutes. The test finished when the stress values declined or kept constant [59].

3.5 Shrink-swell cycles

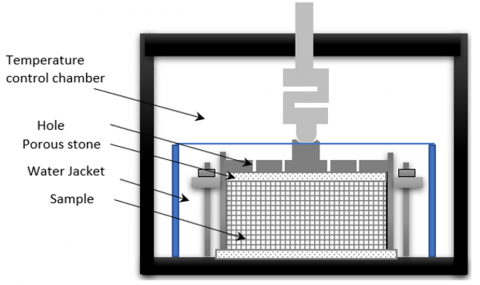

To explore the influence of adding glass on the shrink-swell behavior after achieving equilibrium, the shrink-swell tests were carried out. These experiments were conducted to explore how lime stabilization affects the swell-shrink behavior once the samples reach an equilibrium state, where equal swelling and shrinkage deformations occur in each cycle. The specimens were compacted at the OMC and MDD, then exposed to cycles of swelling and shrinking following the methodology outlined by Tripathy et al. [45]. These tests were conducted using the oedometer device with modifications (refer to Figure 3) to facilitate sample shrinkage under pressure of 6.7 kPa and temperature of 40℃. The apparatus was positioned within a controlled-temperature environmental chamber to manage and uphold the desired temperature. Samples were immersed in water and allowed to swell at room temperature while monitoring vertical movements. Once swelling changes became insignificant, the reverse shrinkage process began. Initially, water was removed from the inner cell, and subsequently, the oedometer cells were introduced into the chamber, where they were kept at a consistent temperature o of 40℃ while maintaining a pressure of 6.7 kPa. This marked the completion of the first swell-shrink cycle. After the shrinkage process, the sample was gradually returned to the normal room temperature over a period of 2 to 3 hours. Then, the samples were immersed in water starting the second cycle of swelling and shrinking. Subsequently, the samples were submerged in water to commence the second cycle of swelling and shrinking. This process was iterated until equilibrium condition was attained. Eventually, the axial strain and swelling/shrinkage vs number of cycles were drawn.

Figure 3. Modified oedometer cell

Only limitation of carrying out this test is the potential for inadequate procedure in achieving equilibrium condition. There are three factors affect the accuracy of reaching the equilibrium condition. These factors include measurement tools, environmental conditions, and sample preparation techniques. The complexity of soil behavior, especially with additives such as crushed glass, complicates result interpretation across cycles. Despite a structured methodology, addressing equilibrium limitations is crucial for robust experimental data.

4.1 Consistency limits

Following the ASTM-D4318 [60], the liquid limit, plastic limit and plasticity index (LL, PLand PI, respectively) were obtained for the blends at different G contents and presented in Figure 4, which presents reductions in LL and PI as glass content increased. It was crucial to note that a further decrease in the Plasticity Index (PI) was expected for all mixtures. However, the G blend had around 12% of particle sizes finer than 0.425 mm (refer to Figure 2). This suggested that the blend, e.g., with 30% C-70% G had about 30% clay and 8.4% glass < 0.425 mm. Hence, the reduction in Plasticity Index (PI) was dependent on the particle size distribution (PSD) of glass finer than 0.425 mm. According to ASTM-D2487 [61], blends consisting of 100% clay (C), 80% clay-20% glass (G), 70% clay-30% glass, 60% clay-40% glass, and 50% clay-50% glass can be classified as clay with high plasticity (CH) (Table 1). However, blends containing 40% clay-60% glass, 30% clay-70% glass, and 20% clay-80% glass can be categorized as sandy clay (Sc). The blend of 100 G can be classified as well-graded sand (SW). According to the reactive soils classification estimated by the PI [62] demonstrated in Table 2, the blends with glass contents ≥ 60% can be categorized as low reactive soil. Thus, 60% glass content was recommended as optimum glass content.

Figure 4. LL and PI for different blends

Table 2. Classification of reactive soils

|

Expansivity |

Low |

Medium |

High |

Very High |

|

PI (%) [60] |

< 20 |

12-34 |

23-45 |

> 32 |

|

Swelling (%) [56] |

0-1.5 |

1.5-5 |

5-25 |

> 25 |

4.2 Compaction characteristics

Following the ASTM-D698 [55] procedure, the OMC and MDD for all blends were measured using the standard Proctor compaction test. Figure 5 illustrates that, for a particular blend, the dry density raised as moisture content raised until reaching the OMC, after which the dry density decreased. Figures 6 and 7 demonstrate that as glass content increased, the MDD increased and OMC decreased. The reduction in the OMC attributed to the feasibility of glass particles to absorb water which is lower than clay particles. Besides, the samples with higher glass content achieved higher MDD which consequently caused less available voids to be filled with water. These outcomes are consistent with the outcomes of Ibrahim et al. [63]. The blend pattern-OMC and blend pattern-MDD relationships can be expressed by Eqs. (1) and (2), respectively.

Figure 5. Compaction characteristics of clay at different crushed glass contents

Figure 6. MDD for clay at various crushed glass contents

Figure 7. OMC for clay at various crushed glass contents

$\begin{gathered}M D D=0.00018 n^4-0.0013 n^3-0.0168 n^2 +0.2901 n+15.112 \\ \mathrm{R}^2=0.9917\end{gathered}$ (1)

$\begin{gathered}O M C=-0.0312 n^3+0.3768 n^2-2.9761 n +26.103 \\ \mathrm{R}^2=0.9964\end{gathered}$ (2)

where, n is a blend pattern, n= 1, 2, 3, 4, 5, 6, 7, 8 and 9. n =1 and 2 describe blends of C and 0.8-C-0.2 G.

4.3 One-dimensional swell test

1-D swell test results shown in Figure 8 presents that the specimens at 0% glass content swelled to reach 8.5% and according to the categorization conducted by Seed et al. [56], the clay specimen was categorized as high-reactive soils. Adding about 17% glass contributed to reducing swelling and converted the categorization from high to moderate and from moderate to low after adding about 35% glass. This is due to the increase in glass content would increase the glass particles contacts and the clay role would be inactive and thus minor swelling could be achieved. Eq. (3) describes the influence of adding glass on soil swell values. The findings of the 1-D swell test recommended 35% glass content to be the optimum.

$\begin{aligned} { Swelling }(\%)= & 0.0116 m^4-0.3297 m^3 +2.490 m^2-10.018 m+16.356 \\ & \mathrm{R}^2=0.9989\end{aligned}$ (3)

Figure 8. Swelling potential for clay with various crushed glass contents

4.4 Strength characteristics

Figure 9 presents the influence of adding recycled glass on the UCS of the reactive clay. The glass content has a slight influence on the soil samples strength treated with 20% recycled glass. Yet, notable impact was observed in specimens treated with 30% and 40% recycled glass. After that, a slight increase was observed after adding 50% glass. These results confirmed the mechanism of stabilization mentioned in Section 3.3. After adding 40% recycled glass, the particles of clay were fully confined in voids among glass particles and consequently, the clay role was inactive. Thus, the UCS results suggested 40% glass content to be the optimum glass content.

Figure 9. Variation of UCS with recycled glass proportions

4.5 Shrink-swell cycles test

Based on 1-D swell and UCS outcomes, adding 35% and 40% of glass were recommended to be sufficient to improve the clay properties. Therefore, for the long-term, the influence of shrink-swell cycles was explored for the blends of 100% C, 65% C-35% G and 60% C-40% G. For the clay specimen, Figure 10 presents that the equilibrium was obtained at the end of the cycle three. Moreover, the swelling at the first cycle (after compaction) was about 9% and by the end of the second cycle, this value increased to approximately twice its initial value, reaching around 18%. The specimens at the end of cycle two were also categorized as highly reactive clay [56]. Next, the swelling values oscillated till achieving similar shrinkage and swelling deformation as shown in Figures 10 and 11.

Figure 10. Strain vs shrink-swell cycles for blends of 100% clay, 60% clay-40% glass and 65% clay-35% glass

Figure 11. Shrinkage/swelling vs shrink-swell cycles for blends of 100% clay, 60% clay-40% glass and 65% clay-35% glass

At equilibrium, the shrinkage and swelling values were 14.5%. Therefore, considering the clay behavior and particularly reactive soil regardless of cyclic oscillation may underestimate the soil swelling. For the specimens of 65% C-35% G and 60% C-40% G, the shrinkage and swelling values were not affected by the cyclic shrink-swell (i.e., 1.2% and 1% for the blends of 65% C-35% G and 60% C-40% G, respectively). Therefore, it is adequate to consider the maximum swelling reached during the first cycle for design purposes. These outcomes approved the nomination of 35% glass content as the optimal.

Reactive soil with different glass contents blends was studied to enhance the traditional backfill material. Experimental testing being specific gravity, PSD, Consistency limits, compaction tests were conducted to explore the physical properties of various blends. One-dimensional swell, unconfined compressive strength and shrink-swell cycles tests were investigated for short and long-term performance. The main findings were as follows:

(1) The MDD increased and OMC decreased as glass content increased.

(2) The outcome of the Consistency limits suggested selecting 60% glass as optimum glass content.

(3) One-dimensional swell, unconfined compressive strength and shrink-swell cycles tests approved that the optimum glass content was 35%.

The optimum recycled glass content suggested in this study applies specifically to coarse recycled glass with a size below 2.36 mm, representing the limitation of this study.

The objective of the present research was to encourage the utilization of recycled glass in improving challenging subgrades, offering an alternative to traditional stabilization techniques. As a result, this reduces the problem of waste stockpiling and environmental issues. Future endeavors may involve establishing a test site for long term monitoring of a field test section, aiming to validate laboratory findings. Additionally, using crushed glass in pavement application and that would require applying dynamic tests, including repeated load tests to simulate pavement loads. The findings of this study improve the industry’s confidence in using waste material to enhance the properties of soils and as a result, this reduces the problem of waste stockpiling and environmental issues.

[1] Al-Taie, A., Disfani, M., Evans, R., Arulrajah, A., Horpibulsuk, S. (2018). Impact of curing on behaviour of basaltic expansive clay. Road Materials and Pavement Design, 19(3): 624-645. https://doi.org/10.1080/14680629.2016.1267660

[2] Al-Taie, A., Disfani, M., Evans, R., Arulrajah, A. (2020). Effect of swell–shrink cycles on volumetric behavior of compacted expansive clay stabilized using lime. International Journal of Geomechanics, 20(11): 04020212. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001863

[3] Khademi, F., Budiman, J. (2016). Expansive soil: causes and treatments. i-Manager's Journal on Civil Engineering, 6(3): 1.

[4] Al-Taie, A., Disfani, M., Evans, R., Arulrajah, A., Horpibulsuk, S. (2019). Volumetric behavior and soil water characteristic curve of untreated and lime-stabilized reactive clay. International Journal of Geomechanics, 19(2): 04018192. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001336

[5] Al-Taie, A., Disfani, M.M., Evans, R., Arulrajah, A., Yaghoubi, E. (2021). Impact of lime stabilization on swelling and soil water retention behavior of expansive subgrade. In Advances in Transportation Geotechnics IV: Proceedings of the 4th International Conference on Transportation Geotechnics Volume 1, Switzerland, pp. 769-780. https://doi.org/10.1007/978-3-030-77230-7_58

[6] Jawad, I.T., Taha, M.R., Majeed, Z.H., Khan, T.A. (2014). Soil stabilization using lime: Advantages, disadvantages and proposing a potential alternative. Research Journal of Applied Sciences, Engineering and Technology, 8(4): 510-520.

[7] Indraratna, B., Athukorala, R., Vinod, J. (2013). Estimating the rate of erosion of a silty sand treated with lignosulfonate. Journal of Geotechnical and Geoenvironmental Engineering, 139(5): 701-714. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000766

[8] Firoozi, A.A., Guney Olgun, C., Firoozi, A.A., Baghini, M.S. (2017). Fundamentals of soil stabilization. International Journal of Geo-Engineering, 8: 1-16. https://doi.org/10.1186/s40703-017-0064-9

[9] Wang, Q., Tang, A.M., Cui, Y.J., Delage, P., Barnichon, J.D., Ye, W.M. (2013). The effects of technological voids on the hydro-mechanical behaviour of compacted bentonite–Sand mixture. Soils and Foundations, 53(2): 232-245. https://doi.org/10.1016/j.sandf.2013.02.004

[10] Nelson, J.D., Chao, K.C., Overton, D.D., Nelson, E.J. (2015). Soil treatment and moisture control. Foundation Engineering for Expansive Soils, 10: 258-294. https://doi.org/10.1002/9781118996096.ch10

[11] Estabragh, A.R., Pereshkafti, M.R.S., Parsaei, B., Javadi, A.A. (2013). Stabilised expansive soil behaviour during wetting and drying. International Journal of Pavement Engineering, 14(4): 418-427. https://doi.org/10.1080/10298436.2012.746688

[12] Yazdandoust, F., Yasrobi, S.S. (2010). Effect of cyclic wetting and drying on swelling behavior of polymer-stabilized expansive clays. Applied Clay Science, 50(4): 461-468. https://doi.org/10.1016/j.clay.2010.09.006

[13] Yadav, J.S., Tiwari, S.K. (2017). Effect of waste rubber fibres on the geotechnical properties of clay stabilized with cement. Applied Clay Science, 149: 97-110. https://doi.org/10.1016/j.clay.2017.07.037

[14] Bharadwaj, A., Houston, S., Houston, W., Welfert, B., Walsh, K. (2013). Effect of soil replacement option on surface deflections for expansive clay profiles. Arizona State University. https://doi.org/10.1201/b14393-82

[15] Evans, R.P., McManus, K.J. (1999). Construction of vertical moisture barriers to reduce expansive soil subgrade movement. Transportation Research Record, 1652(1): 108-112. https://doi.org/10.3141/1652-48

[16] Dunham-Friel, J., Carraro, J.A.H. (2011). Shear strength and stiffness of expansive soil and rubber (ESR) mixtures in undrained axisymmetric compression. In Geo-Frontiers 2011: Advances in Geotechnical Engineering, United States, pp. 1111-1120. https://doi.org/10.1061/41165(397)114

[17] Seda, J.H., Lee, J.C., Carraro, J.A.H. (2007). Beneficial use of waste tire rubber for swelling potential mitigation in expansive soils. In Soil Improvement, United States, pp. 1-9. https://doi.org/10.1061/40916(235)5

[18] Tam, V.W., Tam, C.M. (2006). A review on the viable technology for construction waste recycling. Resources, Conservation and Recycling, 47(3): 209-221. https://doi.org/10.1016/j.resconrec.2005.12.002

[19] Arabani, M., Sharafi, H., Habibi, M.R., Haghshenas, E. (2012). Laboratory evaluation of cement stabilized crushed glass-sand blends. Electronic Journal of Geotechnical Engineering, 17: 1777-1792.

[20] Yaghoubi, E., Al-Taie, A., Disfani, M., Fragomeni, S. (2022). Recycled aggregate mixtures for backfilling sewer trenches in nontrafficable areas. International Journal of Geomechanics, 22(3): 04021308. https://doi.org/10.1061/(ASCE)GM.1943-5622.0002297

[21] Sabat, A.K. (2012). A study on some geotechnical properties of lime stabilised expansive soil–Quarry dust mixes. International Journal of Emerging Trends in Engineering and Development, 1(2): 42-49.

[22] Rahmat, M.N., Kinuthia, J.M. (2011). Effects of mellowing sulfate-bearing clay soil stabilized with wastepaper sludge ash for road construction. Engineering Geology, 117(3-4): 170-179. https://doi.org/10.1016/j.enggeo.2010.10.015

[23] Bin-Shafique, S., Rahman, K., Yaykiran, M., Azfar, I. (2010). The long-term performance of two fly ash stabilized fine-grained soil subbases. Resources, Conservation and Recycling, 54(10): 666-672. https://doi.org/10.1016/j.resconrec.2009.11.007

[24] Cokca, E., Yazici, V., Ozaydin, V. (2009). Stabilization of expansive clays using granulated blast furnace slag (GBFS) and GBFS-cement. Geotechnical and Geological Engineering, 27: 489-499. https://doi.org/10.1007/s10706-008-9250-z

[25] Sharma, R.S., Phanikumar, B.R., Rao, B.V. (2008). Engineering behavior of a remolded expansive clay blended with lime, calcium chloride, and rice-husk ash. Journal of Materials in Civil Engineering, 20(8): 509-515. https://doi.org/10.1061/(ASCE)0899-1561(2008)20:8(509)

[26] Degirmenci, N., Okucu, A., Turabi, A. (2007). Application of phosphogypsum in soil stabilization. Building and Environment, 42(9): 3393-3398. https://doi.org/10.1016/j.buildenv.2006.08.010

[27] Amu, O., Fajobi, A., Afekhuai, S. (2005). Stabilizing potential of cement and fly ash mixture on expansive clay soil. Journal of Applied Sciences, 5(9): 1669-1673. https://doi.org/10.5555/20053182773

[28] Sudhakar, S., Duraisekaran, E., Dilli Vignesh, G., Kanna, G.D. (2021). Performance evaluation of quarry dust treated expansive clay for road foundations. Iranian Journal of Science and Technology, Transactions of Civil Engineering, 45: 2637-2649. https://doi.org/10.1007/s40996-021-00645-4

[29] Wu, Y., Shi, K., Han, Y., Han, T., Yu, J., Li, D. (2021). Experimental study on strength characteristics of expansive soil improved by steel slag powder and cement under dry–wet cycles. Iranian Journal of Science and Technology, Transactions of Civil Engineering, 45: 941-952. https://doi.org/10.1007/s40996-020-00473-y

[30] Del Rio, D.D.F., Sovacool, B.K., Foley, A.M., Griffiths, S., Bazilian, M., Kim, J., Rooney, D. (2022). Decarbonizing the glass industry: A critical and systematic review of developments, sociotechnical systems and policy options. Renewable and Sustainable Energy Reviews, 155: 111885. https://doi.org/10.1016/j.rser.2021.111885

[31] Javed, S.A., Chakraborty, S. (2020). Effects of waste glass powder on subgrade soil improvement. World Scientific News, 144: 30-42.

[32] Arulrajah, A., Ali, M.M.Y., Disfani, M.M., Horpibulsuk, S. (2014). Recycled-glass blends in pavement base/subbase applications: Laboratory and field evaluation. Journal of materials in Civil Engineering, 26(7): 04014025. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000966

[33] Disfani, M.M., Arulrajah, A., Bo, M.W., Hankour, R.J.W.M. (2011). Recycled crushed glass in road work applications. Waste Management, 31(11): 2341-2351. https://doi.org/10.1016/j.wasman.2011.07.003

[34] Mohajerani, A., Vajna, J., Cheung, T.H.H., Kurmus, H., Arulrajah, A., Horpibulsuk, S. (2017). Practical recycling applications of crushed waste glass in construction materials: A review. Construction and Building Materials, 156: 443-467. https://doi.org/10.1016/j.conbuildmat.2017.09.005

[35] Mohsenian Hadad Amlashi, S., Carter, A., Vaillancourt, M., Bilodeau, J.P. (2020). Physical and hydraulic properties of recycled glass as granular materials for pavement structure. Canadian Journal of Civil Engineering, 47(7): 865-874. https://doi.org/10.1139/cjce-2019-0089

[36] Teodosio, B., Al-Taie, A., Yaghoubi, E., Wasantha, P.L.P. (2022). Satellite imaging techniques for ground movement monitoring of a deep pipeline trench backfilled with recycled materials. Remote Sensing, 15(1): 204. https://doi.org/10.3390/rs15010204

[37] Babatunde, O.A., Sani, J., Sambo, A.H. (2019). Black cotton soil stabilization using glass powder. International Journal of Innovative Research in Science, Engineering and Technology, 8(5): 5208-5214. https://doi.org/10.15680/IJIRSET.2019.0805053

[38] Basari, E. (2012). Effect of granular waste glass on soil properties. In International Conference on New Developments in Soil Mechanics and Geotechnical Engineering, Nicosia, North Cyprus, pp. 479-484.

[39] Benny, J.R., Jolly, J., Sebastian, J.M., Thomas, M. (2017). Effect of glass powder on engineering properties of clayey soil. International Journal of Engineering Research & Technology, 6(5): 228-231.

[40] Fauzi, A., Djauhari, Z., Fauzi, U.J. (2016). Soil engineering properties improvement by utilization of cut waste plastic and crushed waste glass as additive. International Journal of Engineering and Technology, 8(1): 15.

[41] Ikara, I.A., Kundiri, A.M., Mohammed, A. (2015). Effects of waste glass (WG) on the strength characteristics of cement stabilized expansive soil. American Journal of Engineering Research (AJER), 4(11): 33-41.

[42] Sohail, S., Honna, M., Mathad, V., Bharamgoud, B. (2018). Comparative study on soil stabilization using powdered glass and sodium hydro-oxide additives. International Journal for Innovative Research in Science & Technology, 4(12): 86-93.

[43] Kalakada, Z., Doh, J.H., Zi, G. (2020). Utilisation of coarse glass powder as pozzolanic cement—A mix design investigation. Construction and Building Materials, 240: 117916. https://doi.org/10.1016/j.conbuildmat.2019.117916

[44] Ogundairo, T.O., Adegoke, D.D., Akinwumi, I.I., Olofinnade, O.M. (2019). Sustainable use of recycled waste glass as an alternative material for building construction–A review. In IOP Conference Series: Materials Science and Engineering, Ota, Nigeria, p. 012073. https://doi.org/10.1088/1757-899X/640/1/012073

[45] Tripathy, S., Rao, K.S., Fredlund, D.G. (2002). Water content-void ratio swell-shrink paths of compacted expansive soils. Canadian Geotechnical Journal, 39(4): 938-959. https://doi.org/10.1139/t02-022

[46] Fleureau, J.M., Kheirbek-Saoud, S., Soemitro, R., Taibi, S. (1993). Behavior of clayey soils on drying–Wetting paths. Canadian Geotechnical Journal, 30(2): 287-296. https://doi.org/10.1139/t93-024

[47] Fleureau, J.M., Verbrugge, J.C., Huergo, P.J., Correia, A.G., Kheirbek-Saoud, S. (2002). Aspects of the behaviour of compacted clayey soils on drying and wetting paths. Canadian Geotechnical Journal, 39(6): 1341-1357. https://doi.org/10.1139/t02-100

[48] Ikeagwuani, C.C., Nwonu, D.C. (2019). Emerging trends in expansive soil stabilisation: A review. Journal of Rock Mechanics and Geotechnical Engineering, 11(2): 423-440. https://doi.org/10.1016/j.jrmge.2018.08.013

[49] Tripathy, S., Subba Rao, K.S. (2009). Cyclic swell–Shrink behaviour of a compacted expansive soil. Geotechnical and Geological Engineering, 27: 89-103. https://doi.org/10.1007/s10706-008-9214-3

[50] Cabalar, A.F., Karabash, Z., Mustafa, W.S. (2014). Stabilising a clay using tyre buffings and lime. Road Materials and Pavement Design, 15(4): 872-891. https://doi.org/10.1080/14680629.2014.939697

[51] Jafari, M.K., Shafiee, A. (2004). Mechanical behavior of compacted composite clays. Canadian Geotechnical Journal, 41(6): 1152-1167. https://doi.org/10.1139/t04-062

[52] ASTM International. (2010). Standard test methods for specific gravity of soil solids by water pycnometer. D854, 717.

[53] ASTM International. (2012). Standard test method for density, relative density (specific gravity) and absorption of coarse aggregate. C127-12.

[54] ASTM International. (2007). Standard test method for particle size analysis of soils. West Conshohocken, D422.

[55] ASTM International. (2012). Standard test methods for laboratory compaction characteristics of soil using standard effort (12 400 ft-lbf/ft3 (600 kN-m/m3)). West Conshohocken, D698.

[56] Seed, H.B., Woodward Jr, R.J., Lundgren, R. (1962). Prediction of swelling potential for compacted clays. Journal of the Soil Mechanics and Foundations Division, 88(3): 53-87. https://doi.org/10.1061/JSFEAQ.0000431

[57] ASTM International. (2014). Standard test methods for one-dimensional swell or collapse of soils. D4546-14.

[58] ASTM International. (2011). Standard test method for one-dimensional consolidation properties of soils using incremental loading. West Conshohocken, D2435/D2435M.

[59] ASTM International. (2008). Standard test method for unconfined compressive strength of cohesive soil. West Conshohocken, D2166.

[60] ASTM International. (2017). Standard test method for liquid limit, plastic limit, and plasticity index of soils. West Conshohocken, D4318.

[61] ASTM International. (2011). Standard practice for classification of soils for engineering purposes (Unified Soil Classification System). West Conshohocken, D2487.

[62] Holtz, W.G., Gibbs, H.J. (1956). Engineering properties of expansive clays. Transactions of the American Society of Civil Engineers, 121(1): 641-663

[63] Ibrahim, H.H., Mawlood, Y.I., Alshkane, Y.M. (2021). Using waste glass powder for stabilizing high-plasticity clay in Erbil city-Iraq. International Journal of Geotechnical Engineering, 15(4): 496-503. https://doi.org/10.1080/19386362.2019.1647644